Key Insights

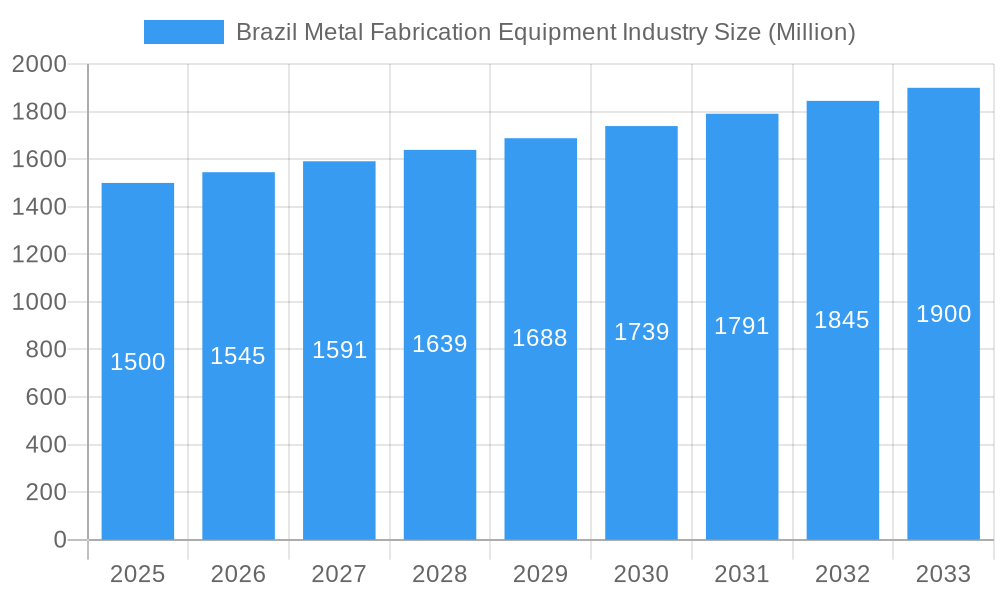

The Brazilian Metal Fabrication Equipment market, estimated at $1.3 billion in the base year of 2025, is projected for significant expansion. Forecasted to achieve a Compound Annual Growth Rate (CAGR) of 2.86% through 2033, this growth is propelled by Brazil's dynamic manufacturing landscape, especially within the automotive, aerospace, and construction industries. Government-led infrastructure modernization and industrial development programs further stimulate market expansion. The increasing integration of automation and Industry 4.0 principles within metal fabrication is also driving demand for advanced, high-precision equipment. Key market participants, including BMA Brazil, Colfax, DMG Mori, and Amada, are strategically positioned to capitalize on these emerging trends. Nevertheless, economic volatility and potential import regulations represent potential headwinds for sustained market growth.

Brazil Metal Fabrication Equipment Industry Market Size (In Billion)

Despite these potential challenges, distinct market segments offer compelling opportunities. While detailed segmentation data is limited, sectors such as laser cutting systems, CNC machining centers, and press brakes are anticipated to lead growth due to their contributions to enhanced efficiency and automation. The market is also trending towards digitally integrated solutions and advanced material processing technologies, creating avenues for solution providers. Regional economic activity within Brazil will influence growth rates, with established industrial centers likely outperforming less developed areas. The market's long-term outlook is intrinsically linked to Brazil's economic stability and ongoing investment in manufacturing technology upgrades. Furthermore, a growing emphasis on sustainability and energy efficiency in manufacturing will shape future equipment demand.

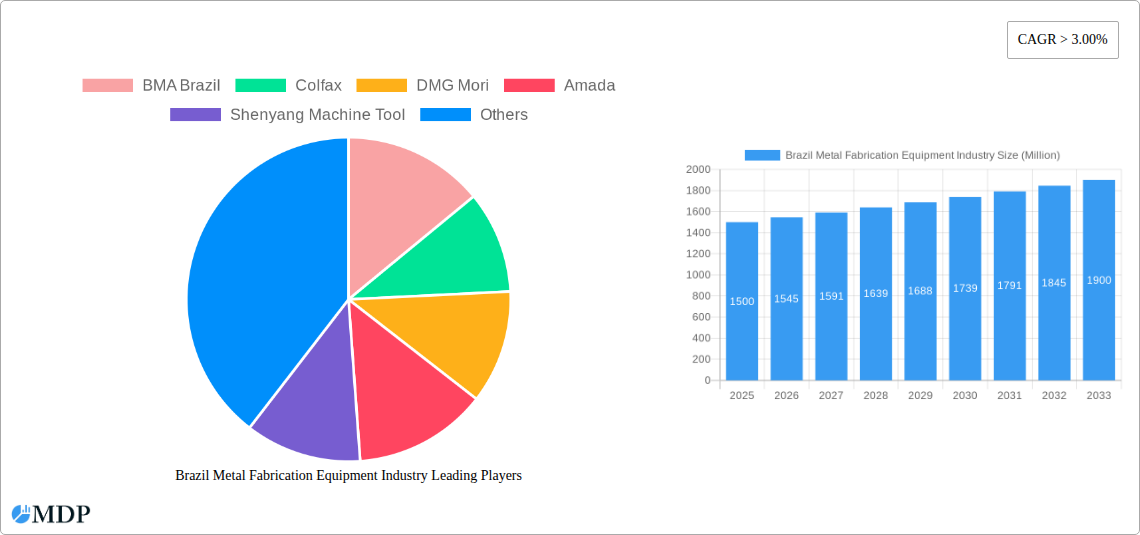

Brazil Metal Fabrication Equipment Industry Company Market Share

Brazil Metal Fabrication Equipment Industry: A Comprehensive Market Report (2019-2033)

This in-depth report provides a comprehensive analysis of the Brazil metal fabrication equipment industry, offering invaluable insights for stakeholders, investors, and industry professionals. Covering the period from 2019 to 2033, with a focus on 2025, this report unveils market dynamics, growth drivers, challenges, and future opportunities. Unlock actionable intelligence and gain a competitive edge with our data-driven analysis.

Keywords: Brazil metal fabrication equipment market, metal fabrication industry Brazil, metalworking machinery Brazil, sheet metal equipment Brazil, welding equipment Brazil, CNC machines Brazil, industrial automation Brazil, Brazil manufacturing equipment, metal fabrication market size Brazil, metal fabrication market share Brazil, Brazil metal fabrication equipment forecast.

Brazil Metal Fabrication Equipment Industry Market Dynamics & Concentration

The Brazilian metal fabrication equipment market, valued at $XX Million in 2025, exhibits a moderately concentrated landscape. While a few multinational players like Amada and DMG Mori hold significant market share (estimated at xx% and xx% respectively in 2025), several domestic players and smaller specialized firms contribute to a competitive ecosystem. Innovation is driven primarily by the demand for advanced automation, particularly in sectors like automotive and construction. Regulatory frameworks, including those related to safety and environmental compliance, significantly impact market dynamics. Product substitutes, such as 3D printing for certain applications, pose a growing albeit niche challenge. End-user trends lean towards increased efficiency, precision, and customization. M&A activity in the sector has been relatively moderate in recent years, with approximately xx deals recorded between 2019 and 2024. The increasing adoption of Industry 4.0 technologies and the government's focus on infrastructure development are expected to boost the market further.

- Market Concentration: Moderately concentrated, with top players holding approximately xx% market share in 2025.

- Innovation Drivers: Automation, precision, customization, Industry 4.0 technologies.

- Regulatory Impact: Safety and environmental regulations significantly influence market growth.

- M&A Activity: Approximately xx deals between 2019 and 2024.

- Substitute Products: 3D printing technologies pose a limited threat.

Brazil Metal Fabrication Equipment Industry Trends & Analysis

The Brazilian metal fabrication equipment market is projected to experience a CAGR of xx% during the forecast period (2025-2033), driven by robust growth across key sectors like automotive, construction, and energy. Technological disruptions, particularly the increased adoption of CNC machines, robotics, and advanced automation systems, are reshaping the industry landscape. Consumer preferences are shifting towards greater precision, higher production efficiency, and improved product quality. Competitive dynamics are characterized by both price competition and differentiation based on technology and service offerings. Market penetration of advanced technologies remains relatively low, presenting substantial opportunities for growth. This growth is further fueled by increasing government investment in infrastructure projects and the growing demand for locally produced goods. The market's development is closely linked to the overall economic health of Brazil.

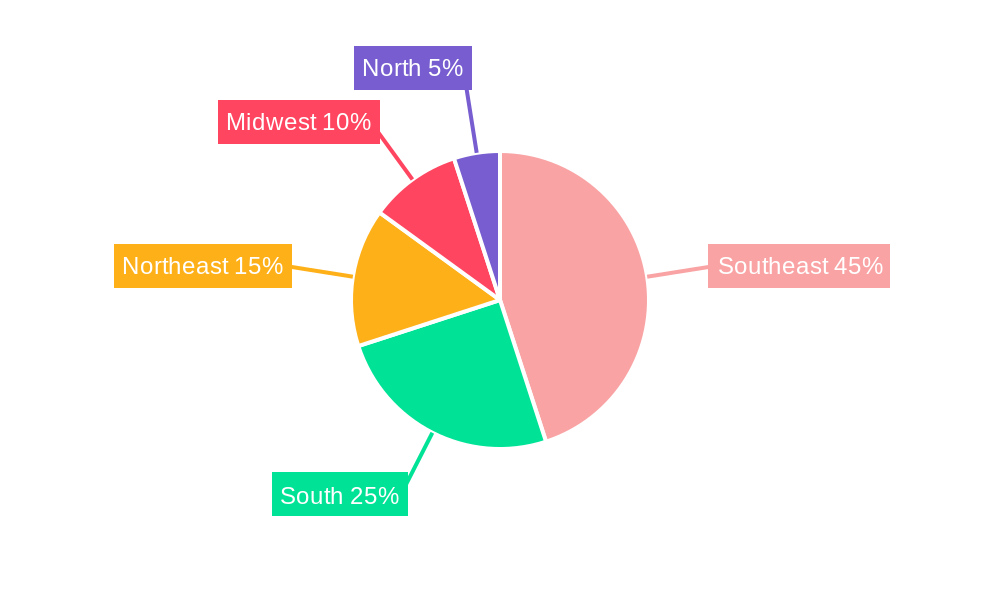

Leading Markets & Segments in Brazil Metal Fabrication Equipment Industry

The Southeast region of Brazil dominates the metal fabrication equipment market due to its concentration of manufacturing industries and robust infrastructure. São Paulo, in particular, stands out as a key market hub. The automotive segment represents a significant portion of the overall market demand due to a large automotive manufacturing base.

Key Drivers for Southeast Region Dominance:

- Concentrated manufacturing base

- Developed infrastructure (transportation, logistics)

- Strong automotive industry presence

- Proximity to major ports

Automotive Segment Dominance:

- High demand for advanced manufacturing equipment.

- Investment in automation and production efficiency.

- Stringent quality control requirements.

The strong presence of major automotive manufacturers in the Southeast region fuels the demand for advanced metal fabrication equipment and contributes significantly to the regional dominance in the market. The construction segment is also showing robust growth due to government infrastructure projects.

Brazil Metal Fabrication Equipment Industry Product Developments

Recent product developments focus on enhanced automation, precision, and integration capabilities. The market is witnessing a surge in the adoption of CNC machines, robotic welding systems, and laser cutting technologies, all contributing to higher productivity and reduced operational costs. These advancements cater to the growing need for customized and high-quality products within various manufacturing sectors. Manufacturers are also focusing on developing user-friendly interfaces and providing comprehensive after-sales service packages to enhance customer satisfaction.

Key Drivers of Brazil Metal Fabrication Equipment Industry Growth

The growth of the Brazilian metal fabrication equipment industry is propelled by several factors: increasing industrial automation, government initiatives promoting infrastructure development (leading to higher demand for construction equipment), and a growing emphasis on domestic manufacturing. Further, the expanding automotive and renewable energy sectors contribute substantially to the demand for specialized metal fabrication equipment. Favorable government policies and initiatives aimed at boosting industrial growth also positively influence market expansion.

Challenges in the Brazil Metal Fabrication Equipment Industry Market

The industry faces challenges such as economic volatility, fluctuating currency exchange rates impacting import costs, and a relatively high cost of labor. Furthermore, supply chain disruptions and competition from both domestic and international players pose significant hurdles to market growth. These challenges impact profitability and necessitate strategic adjustments by industry players. The fluctuating Brazilian Real also adds to the uncertainty in pricing and investment decisions.

Emerging Opportunities in Brazil Metal Fabrication Equipment Industry

The industry is poised for growth driven by technological advancements in areas like additive manufacturing (3D printing) and the increasing adoption of Industry 4.0 technologies. Strategic partnerships between domestic and international players can facilitate technology transfer and access to advanced solutions. Expansion into niche markets, such as aerospace and medical equipment manufacturing, offers lucrative opportunities for specialized equipment providers.

Leading Players in the Brazil Metal Fabrication Equipment Industry Sector

- BMA Brazil

- Colfax

- DMG Mori

- Amada

- Shenyang Machine Tool (Note: English language website may be limited)

- Hurco

- Kennametal

- MAG Giddings & Lewis

- List Not Exhaustive

Key Milestones in Brazil Metal Fabrication Equipment Industry Industry

- 2020: Increased adoption of automation technologies in response to labor shortages.

- 2021: Government initiatives to support infrastructure development fueled demand.

- 2022: Several mergers and acquisitions aimed at consolidating market share.

- 2023: Launch of several new models of CNC machines with enhanced capabilities.

- 2024: Growing interest in sustainable manufacturing practices and green technologies.

Strategic Outlook for Brazil Metal Fabrication Equipment Market

The Brazilian metal fabrication equipment market presents a significant growth potential, driven by ongoing industrialization, infrastructural investments, and the increasing adoption of advanced manufacturing technologies. Companies focusing on innovation, strategic partnerships, and adaptation to evolving market demands will be best positioned to capture this growth. Investing in advanced automation, providing comprehensive customer support, and leveraging Industry 4.0 technologies will be crucial for sustained success in this dynamic market.

Brazil Metal Fabrication Equipment Industry Segmentation

-

1. Product type

- 1.1. Automatic

- 1.2. Semi - automatic

- 1.3. Manual

-

2. Equipment type

- 2.1. Cutting

- 2.2. Machining

- 2.3. Forming

- 2.4. Welding

- 2.5. Other Equipment Types

-

3. End User industry

- 3.1. Oil and Gas

- 3.2. Manufacturing

- 3.3. Power and Utilities

- 3.4. Construction

- 3.5. Other End-user Industries

Brazil Metal Fabrication Equipment Industry Segmentation By Geography

- 1. Brazil

Brazil Metal Fabrication Equipment Industry Regional Market Share

Geographic Coverage of Brazil Metal Fabrication Equipment Industry

Brazil Metal Fabrication Equipment Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 2.86% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Manufacturing sector promises a greater boom in the region for the metal fabrication equipment market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Brazil Metal Fabrication Equipment Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Product type

- 5.1.1. Automatic

- 5.1.2. Semi - automatic

- 5.1.3. Manual

- 5.2. Market Analysis, Insights and Forecast - by Equipment type

- 5.2.1. Cutting

- 5.2.2. Machining

- 5.2.3. Forming

- 5.2.4. Welding

- 5.2.5. Other Equipment Types

- 5.3. Market Analysis, Insights and Forecast - by End User industry

- 5.3.1. Oil and Gas

- 5.3.2. Manufacturing

- 5.3.3. Power and Utilities

- 5.3.4. Construction

- 5.3.5. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Brazil

- 5.1. Market Analysis, Insights and Forecast - by Product type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 BMA Brazil

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Colfax

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 DMG Mori

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Amada

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Shenyang Machine Tool

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Hurco

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Kennametal

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 MAG Giddings & Lewis*List Not Exhaustive

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.1 BMA Brazil

List of Figures

- Figure 1: Brazil Metal Fabrication Equipment Industry Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Brazil Metal Fabrication Equipment Industry Share (%) by Company 2025

List of Tables

- Table 1: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Product type 2020 & 2033

- Table 2: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Equipment type 2020 & 2033

- Table 3: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by End User industry 2020 & 2033

- Table 4: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 5: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Product type 2020 & 2033

- Table 6: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Equipment type 2020 & 2033

- Table 7: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by End User industry 2020 & 2033

- Table 8: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Brazil Metal Fabrication Equipment Industry?

The projected CAGR is approximately 2.86%.

2. Which companies are prominent players in the Brazil Metal Fabrication Equipment Industry?

Key companies in the market include BMA Brazil, Colfax, DMG Mori, Amada, Shenyang Machine Tool, Hurco, Kennametal, MAG Giddings & Lewis*List Not Exhaustive.

3. What are the main segments of the Brazil Metal Fabrication Equipment Industry?

The market segments include Product type, Equipment type, End User industry.

4. Can you provide details about the market size?

The market size is estimated to be USD 1.3 billion as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Manufacturing sector promises a greater boom in the region for the metal fabrication equipment market.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Brazil Metal Fabrication Equipment Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Brazil Metal Fabrication Equipment Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Brazil Metal Fabrication Equipment Industry?

To stay informed about further developments, trends, and reports in the Brazil Metal Fabrication Equipment Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence