Key Insights

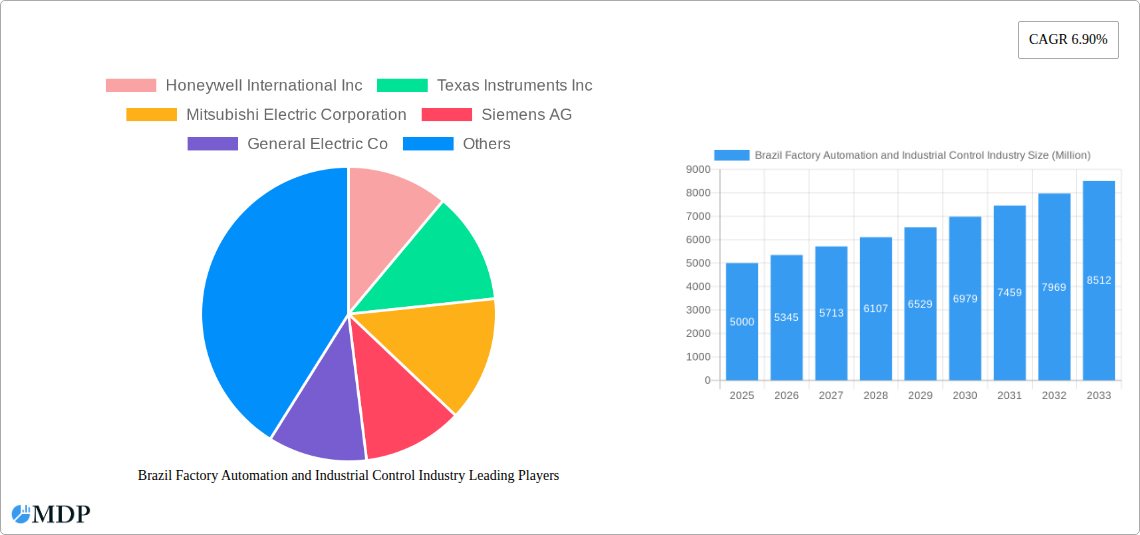

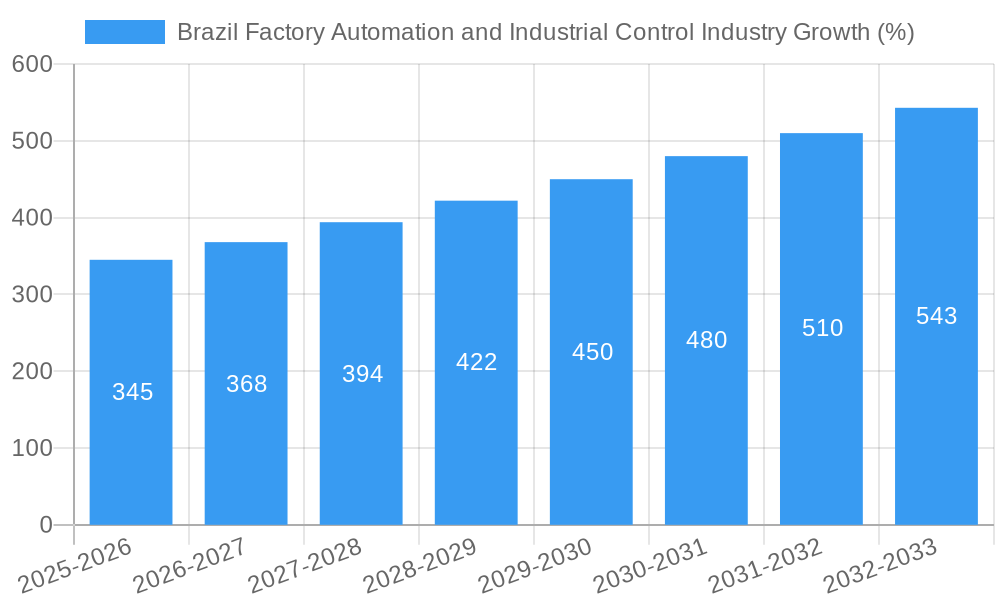

The Brazilian factory automation and industrial control market is experiencing robust growth, driven by increasing government initiatives promoting industrial modernization, a burgeoning manufacturing sector, and the rising adoption of Industry 4.0 technologies. The market's Compound Annual Growth Rate (CAGR) of 6.90% from 2019 to 2024 indicates significant potential. Key drivers include the need for enhanced operational efficiency, improved product quality, and reduced production costs. The automotive, chemical and petrochemical, and power & utilities sectors are major end-users, exhibiting substantial demand for advanced automation solutions. Growth is further fueled by the integration of sophisticated technologies like robotics, artificial intelligence (AI), and the Industrial Internet of Things (IIoT), which enable predictive maintenance, real-time monitoring, and optimized production processes. However, challenges such as high initial investment costs, the need for skilled labor, and cybersecurity concerns may act as restraints to some extent. Segmentation reveals a significant share held by field devices, particularly industrial control systems, reflecting the critical role these play in industrial automation. Leading companies such as Honeywell, Siemens, and Rockwell Automation are actively competing in this dynamic landscape, expanding their product portfolios and strategic partnerships to cater to the growing market needs. The forecast period (2025-2033) is expected to witness continued expansion, largely influenced by ongoing digital transformation initiatives within Brazilian industries.

Based on the provided data and industry trends, the Brazilian factory automation and industrial control market is poised for substantial expansion. The current market size (estimated to be extrapolated from the 2019-2024 data with the 6.9% CAGR) indicates a significant value and volume. The continued growth trajectory is anticipated to be fueled by several converging factors: increased government investments in infrastructure modernization, a favorable business climate encouraging foreign investment in the manufacturing sector, and a rising awareness of the benefits of automation amongst Brazilian businesses. While challenges exist, the positive momentum and opportunities presented by technological advancements suggest a sustained period of robust expansion for the foreseeable future. Competition within the market remains intense, with major international and local players vying for market share. Focusing on innovation, providing tailored solutions, and addressing specific industry needs will be crucial for companies to achieve success in this growth market.

Brazil Factory Automation and Industrial Control Industry: Market Report 2019-2033

This comprehensive report provides an in-depth analysis of the Brazil Factory Automation and Industrial Control Industry, offering valuable insights for stakeholders, investors, and industry professionals. The study period spans from 2019 to 2033, with 2025 serving as the base and estimated year. The forecast period covers 2025-2033, and the historical period encompasses 2019-2024. The market is projected to reach xx Million by 2033, exhibiting a CAGR of xx% during the forecast period. This report meticulously examines market dynamics, leading players, technological advancements, and future growth opportunities within this rapidly evolving sector.

Brazil Factory Automation and Industrial Control Industry Market Dynamics & Concentration

The Brazilian factory automation and industrial control market is characterized by moderate concentration, with several multinational corporations holding significant market share. Key players like Honeywell International Inc, Texas Instruments Inc, Mitsubishi Electric Corporation, Siemens AG, and Rockwell Automation Inc., compete alongside strong local players such as NOVA SMAR SA. The market is driven by increasing government initiatives promoting industrial modernization, rising adoption of Industry 4.0 technologies, and growing investments from both domestic and foreign companies. Regulatory frameworks, while evolving, pose some challenges, primarily related to data security and compliance. Product substitutes are limited, with most solutions providing unique functionalities. The automotive, chemical, and petrochemical sectors are the leading end-users, driving significant demand. Mergers and acquisitions (M&A) activity has been moderate, with xx M&A deals recorded in the last five years, primarily focused on expanding product portfolios and geographical reach. Market share distribution among the top five players is estimated at approximately xx%. Innovation is primarily driven by the need for increased efficiency, improved productivity, and enhanced safety within industrial settings.

Brazil Factory Automation and Industrial Control Industry Industry Trends & Analysis

The Brazilian factory automation and industrial control market demonstrates robust growth, driven by several key factors. The increasing adoption of automation technologies across various end-user industries, particularly in sectors like automotive and food & beverage, is a primary driver. Technological disruptions, such as the emergence of Artificial Intelligence (AI), machine learning (ML), and the Industrial Internet of Things (IIoT), are further accelerating market expansion. Consumer preferences are shifting towards advanced automation solutions that offer greater flexibility, scalability, and integration capabilities. Competitive dynamics are intense, with both global and local players vying for market share. The market exhibits a strong preference for solutions offering higher energy efficiency and reduced environmental impact, aligning with global sustainability goals. The CAGR for the period 2019-2024 is estimated at xx%, while the projected CAGR for 2025-2033 is expected to be xx%. Market penetration of advanced automation technologies remains relatively low, offering significant opportunities for future growth.

Leading Markets & Segments in Brazil Factory Automation and Industrial Control Industry

The automotive sector represents the leading end-user segment, driven by high production volumes and the need for enhanced efficiency in manufacturing processes. The chemical and petrochemical industries follow closely, emphasizing safety and process optimization. Within product segments, industrial control systems hold a larger market share compared to field devices, reflecting the increasing complexity of industrial operations.

- Key Drivers for Automotive: Government incentives for automotive production, rising domestic demand, and the growing electric vehicle (EV) market.

- Key Drivers for Chemical & Petrochemical: Stringent safety regulations, process optimization requirements, and increasing demand for specialized chemicals.

- Key Drivers for Industrial Control Systems: Growing need for centralized control and monitoring, improved data analytics capabilities, and advancements in software solutions.

- Geographic Dominance: The Southeast region of Brazil dominates the market due to its high concentration of industrial activity and established infrastructure.

Brazil Factory Automation and Industrial Control Industry Product Developments

Recent product innovations focus on integrating AI and ML capabilities into industrial control systems, enabling predictive maintenance, real-time optimization, and improved decision-making. The market sees a growing demand for modular and scalable solutions, facilitating easy adaptation to evolving industrial needs. Competitive advantages are increasingly derived from offering robust cybersecurity features, seamless integration with existing infrastructure, and superior customer support.

Key Drivers of Brazil Factory Automation and Industrial Control Industry Growth

Several factors contribute to the market’s growth: Government initiatives promoting industrial automation, increasing investments in infrastructure, the rising adoption of Industry 4.0 technologies, and the growing need for enhanced productivity and efficiency across various industries. For instance, recent tax incentives for companies investing in automation technologies have spurred significant market activity.

Challenges in the Brazil Factory Automation and Industrial Control Industry Market

High initial investment costs associated with implementing automation solutions can be a barrier for smaller companies. Supply chain disruptions and fluctuations in raw material prices also pose challenges. Intense competition among both local and international players can impact profit margins. The relatively high cost of skilled labor needed to implement and maintain automation systems represents another hurdle. Regulatory uncertainties surrounding data security and compliance can also slow down adoption.

Emerging Opportunities in Brazil Factory Automation and Industrial Control Industry

Significant opportunities exist in expanding automation solutions into smaller and medium-sized enterprises (SMEs) and integrating renewable energy sources into industrial processes. The growing focus on sustainability and the increasing adoption of digital twins for industrial processes offer considerable growth potential. Strategic partnerships between technology providers and end-user companies are creating new avenues for innovation and market expansion.

Leading Players in the Brazil Factory Automation and Industrial Control Industry Sector

- Honeywell International Inc

- Texas Instruments Inc

- Mitsubishi Electric Corporation

- Siemens AG

- General Electric Co

- Schneider Electric SE

- NOVA SMAR SA

- Autodesk Inc

- Robert Bosch GmbH

- Rockwell Automation Inc

- Yokogawa Electric Corporation

- Dassault Systemes SE

- ABB Limited

- Aspen Technology Inc

- Emerson Electric Company

Key Milestones in Brazil Factory Automation and Industrial Control Industry Industry

- June 2022: Rockwell Automation partnered with Bravo Motor Company, marking a significant step towards supporting the growth of the EV and battery manufacturing sectors in Brazil. This partnership highlights the increasing focus on sustainable and technologically advanced solutions within the Brazilian industrial landscape.

Strategic Outlook for Brazil Factory Automation and Industrial Control Industry Market

The future of the Brazilian factory automation and industrial control market is bright, driven by sustained industrial growth, increasing government support, and the continuous adoption of advanced technologies. Strategic partnerships, focusing on co-innovation and integrated solutions, will play a crucial role in shaping the market landscape. The focus on sustainability and the integration of renewable energy sources will open up new opportunities for innovative solution providers. The market is poised for significant growth, driven by strong technological advancements and a favorable economic environment.

Brazil Factory Automation and Industrial Control Industry Segmentation

-

1. Product

-

1.1. Field Devices

- 1.1.1. Machine Vision

- 1.1.2. Robotics

- 1.1.3. Sensors

- 1.1.4. Mortor and Drivers

- 1.1.5. Relays and Switches

- 1.1.6. Other Field Devices

-

1.2. Industrial Control Systems

- 1.2.1. SCADA

- 1.2.2. DCS

- 1.2.3. PLC

- 1.2.4. MES

- 1.2.5. PLM

- 1.2.6. ERP

- 1.2.7. HMI

- 1.2.8. Other Industrial Control Systems

-

1.1. Field Devices

-

2. End-user Industry

- 2.1. Automotive

- 2.2. Chemical and Petrochemical

- 2.3. Power and Utilities

- 2.4. Pharmaceutical

- 2.5. Food and Beverage

- 2.6. Oil and Gas

- 2.7. Other End-user Industries

Brazil Factory Automation and Industrial Control Industry Segmentation By Geography

- 1. Brazil

Brazil Factory Automation and Industrial Control Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 6.90% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Focus Toward Cost-cutting and Business Process Improvement; Increasing Adoption of Internet of Things (IoT) and Machine- to-Machine Technologies

- 3.3. Market Restrains

- 3.3.1. High Installation Costs and Lack of Skilled Workforce Preventing Enterprises from Full-scale Adoption of Factory Automation

- 3.4. Market Trends

- 3.4.1. Automotive is One of the Major Segment Driving the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Brazil Factory Automation and Industrial Control Industry Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Product

- 5.1.1. Field Devices

- 5.1.1.1. Machine Vision

- 5.1.1.2. Robotics

- 5.1.1.3. Sensors

- 5.1.1.4. Mortor and Drivers

- 5.1.1.5. Relays and Switches

- 5.1.1.6. Other Field Devices

- 5.1.2. Industrial Control Systems

- 5.1.2.1. SCADA

- 5.1.2.2. DCS

- 5.1.2.3. PLC

- 5.1.2.4. MES

- 5.1.2.5. PLM

- 5.1.2.6. ERP

- 5.1.2.7. HMI

- 5.1.2.8. Other Industrial Control Systems

- 5.1.1. Field Devices

- 5.2. Market Analysis, Insights and Forecast - by End-user Industry

- 5.2.1. Automotive

- 5.2.2. Chemical and Petrochemical

- 5.2.3. Power and Utilities

- 5.2.4. Pharmaceutical

- 5.2.5. Food and Beverage

- 5.2.6. Oil and Gas

- 5.2.7. Other End-user Industries

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Brazil

- 5.1. Market Analysis, Insights and Forecast - by Product

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2024

- 6.2. Company Profiles

- 6.2.1 Honeywell International Inc

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Texas Instruments Inc

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Mitsubishi Electric Corporation

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Siemens AG

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 General Electric Co

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Schneider Electric SE

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 NOVA SMAR SA*List Not Exhaustive

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Autodesk Inc

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Robert Bosch GmbH

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Rockwell Automation Inc

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 Yokogawa Electric Corporation

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Dassault Systemes SE

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.13 ABB Limited

- 6.2.13.1. Overview

- 6.2.13.2. Products

- 6.2.13.3. SWOT Analysis

- 6.2.13.4. Recent Developments

- 6.2.13.5. Financials (Based on Availability)

- 6.2.14 Aspen Technology Inc

- 6.2.14.1. Overview

- 6.2.14.2. Products

- 6.2.14.3. SWOT Analysis

- 6.2.14.4. Recent Developments

- 6.2.14.5. Financials (Based on Availability)

- 6.2.15 Emerson Electric Company

- 6.2.15.1. Overview

- 6.2.15.2. Products

- 6.2.15.3. SWOT Analysis

- 6.2.15.4. Recent Developments

- 6.2.15.5. Financials (Based on Availability)

- 6.2.1 Honeywell International Inc

List of Figures

- Figure 1: Brazil Factory Automation and Industrial Control Industry Revenue Breakdown (Million, %) by Product 2024 & 2032

- Figure 2: Brazil Factory Automation and Industrial Control Industry Share (%) by Company 2024

List of Tables

- Table 1: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by Region 2019 & 2032

- Table 2: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by Product 2019 & 2032

- Table 3: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by End-user Industry 2019 & 2032

- Table 4: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by Region 2019 & 2032

- Table 5: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by Country 2019 & 2032

- Table 6: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by Product 2019 & 2032

- Table 7: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by End-user Industry 2019 & 2032

- Table 8: Brazil Factory Automation and Industrial Control Industry Revenue Million Forecast, by Country 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Brazil Factory Automation and Industrial Control Industry?

The projected CAGR is approximately 6.90%.

2. Which companies are prominent players in the Brazil Factory Automation and Industrial Control Industry?

Key companies in the market include Honeywell International Inc, Texas Instruments Inc, Mitsubishi Electric Corporation, Siemens AG, General Electric Co, Schneider Electric SE, NOVA SMAR SA*List Not Exhaustive, Autodesk Inc, Robert Bosch GmbH, Rockwell Automation Inc, Yokogawa Electric Corporation, Dassault Systemes SE, ABB Limited, Aspen Technology Inc, Emerson Electric Company.

3. What are the main segments of the Brazil Factory Automation and Industrial Control Industry?

The market segments include Product, End-user Industry.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

Focus Toward Cost-cutting and Business Process Improvement; Increasing Adoption of Internet of Things (IoT) and Machine- to-Machine Technologies.

6. What are the notable trends driving market growth?

Automotive is One of the Major Segment Driving the Market.

7. Are there any restraints impacting market growth?

High Installation Costs and Lack of Skilled Workforce Preventing Enterprises from Full-scale Adoption of Factory Automation.

8. Can you provide examples of recent developments in the market?

June 2022 - Rockwell Automation partnered with Bravo Motor Company, a California-based company that provides applied innovation in the field of decarbonization, with a focus on the production of batteries, vehicles, and energy storage systems. Through the new alliance, Rockwell Automation will contribute to the provision of advanced solutions for the manufacture of electric vehicles (EVs) and batteries in the Brazilian market.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Brazil Factory Automation and Industrial Control Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Brazil Factory Automation and Industrial Control Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Brazil Factory Automation and Industrial Control Industry?

To stay informed about further developments, trends, and reports in the Brazil Factory Automation and Industrial Control Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence